Supercal 531 manual verification#

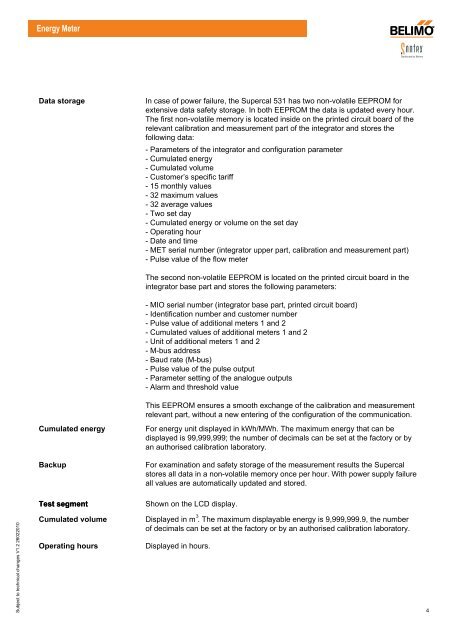

FT-531-e-03.doc Page - 1 Subject to technical alterations Sontex SAĢ Main features Ordering Power supply module Options combinations: Optional communication module: Data storage - Mains or battery powered - Exchangeable integrator module, the wiring base with the connections remain in place - Communication options and functions can be equipped later and without compromising verification of the integrator - EEPROM for the communication setup is pre-installed in the base part - Programming of the specific installation data over two pushbuttons - Fast support via the Internet - Self-recognition of options and voltage supply - M-Bus according to EN1434 (300 38'400 baud) variable and fix data structure - Two or four wire connection techniques - Up to 4 analogue outputs, M-Bus, two open collector outputs and two pulse inputs can be simultaneously used - Clear and customer-friendly user concept - Accuracy better than required by EN 1434 The Supercal 531 disposes, as standard, over an optical interface according to IEC1107, two pulse inputs for additional meters as well as two open collector outputs. From the mean flow rate, the temperature difference and the heat coefficient will be calculated the energy of the captured medium and displayed on the 8-digit LCD display. The recording flow rate is dependant on the pulse value of the flow sensor unit and is constantly updated. Measurement technique The Supercal 531 with mains power supply records every 3 seconds the supply and the return temperature, with battery power every 20 seconds (D-type battery) or 30 seconds (C-type battery). The isolation regulations must be observed! Extensive information about temperature sensors you can find in our Sontex temperature sensor overview. The temperature sensors in cooling systems should not be totally isolated. The active measuring temperature sensor tip must be placed in the centre of the pipe cross section. The temperature sensors can be alternatively installed either in protection pockets or directly in the heating or cooling medium. In the case of unequal cable lengths or cables longer than 6 m we recommend the use of 4-wire sensors. In this case, the shield must be mounted correctly. In the case of temperature sensor pairs with a cable longer than 3 m, we recommend the exclusive use of shielded temperature sensors.

They are always supplied in pairs and must not be separated, extended or shortened. The temperature sensors are matched to one another. Temperature sensors The standard production version of the Supercal 531 integrator is for the Pt 500, but a version for the Pt 100 can also be produced upon request. Consumption values can easily be read on the LCD display, via the optical interface, RS-232, M-bus or modem. The additional pulse inputs allow the connection of hot water, cold water, gas, oil and electricity meters. The pulse value can be modified one single time by means of the push button.

The volume input value is defined when the unit is produced. The factor of the pulse value is defined in the flow meter unit.

Volume inputs can be combined with mechanical, magnetic-inductive, ultrasonic or fluidic oscillators flow sensors with a maximum nominal flow rate of 10'000 m 3 /h. 1 The multi-functional integrator Supercal 531 Design The Supercal 531 integrator is suitable for connecting Pt 500 or Pt 100 temperature sensor pairs with 2 or 4-conducting wire techniques.

0 kommentar(er)

0 kommentar(er)